The Problem of Biofouling

Is defined as the accumulation of unwanted microorganisms, plants, algae and/or animals on a surface in contact with sea water, that due to the formation of biofilm, the subsequent growth of microorganisms happens.

The growth of these microorganisisms has negative effects, biofouling accelerates the corrosion of metallic structures, it also increases the vulnerability of submerged equipment, it reduces its performance, it increases the weight and roughness of structures, which in the case of boats, it increases their friction with water causing an increase in fuel and greenhouse gases.

Biological fouling currently causes great economic losses and environmental damage in sectors such as shipping, the agricultural industry, hydrogeneration and power generation in general, desalination, propulsion or heat exchange.

ENVIRONMENTAL IMPACT

The current variety of procedures against unwanted biofouling have the disadvantage of having a negative impact in the environment. Anti-fouling paints have been used for years. In recent years, legislation has banned or limited the use of certain chemical compounds used in these types of paints due to their highly polluting effect. Restrictions on the use of tributyltin (TBT), chlorothalonil, dichlofluoroamide, Sea-Nine 211, Diuron, Irgarol 1051 and zinc pyrithione, which has increased the use of other elements such as copper and other highly contaminating, easily bioaccumulative heavy metals that can easily increase the food chain reaching humans. Toxins can penetrate the human skin and attack its nerve endings. The harmful effects on individuals vary according to their tolerance levels.

Scientific studies have found high concentrations of copper, cadmium, lead and zinc in algae, fish and other marine organisms. Significant effects of the components of antifouling paints have been reported in reduced reproduction and growth of organisms, increased frequency of tissue alterations and increased mortality.

To illustrate, the level of copper and zinc in Swedish waters exceeded 140 and 340 times the levels allowed by its legislation for copper and zinc. In other waters with boating activity, levels 16,10 and 15 times higher concentrations of Cu, Zn and Pb have been found than in areas not affected by boating that, remain in the river or lake bed for centuries.

ECONOMIC IMPACT

The economic feasibility of our anti-fouling technology is mainly based on the reduction of costs (savings in maintenance and in manufacture). Below, you can see some economic losses over different sectors.

- In general, it is estimated that unwanted biofouling generates losses of up to 0.25% of GDP in most developed countries.

In the case of the petrochemical industry, biofouling reduces exchange efficiency by up to 30%, which is attributed to an annual cost of $16 billion per year in the US and the UK.

- In the power industry fouling is a serious economic problem, fouling control in power plants and desalination plants (water inlets, pipelines, heat exchangers) causes global costs of $15 billion per year, and in the case of membranes used for wastewater treatment it is 1 billion euros per year. For the case of seawater-cooled condensers, an extra fuel cost of $350,000 is estimated for a plant with six 240 MW condensers. In the Colorado River generation systems (USA) generates an increase in maintenance costs of US$80,000 per year per generator, (AMBIO website).

- The U.S. coastal industry estimates that zebra mussels will generate a total of $3.1 billion in damages over the next 10 years (U.S. State Department website). Their cost to 13 power plants on the Columbia River is estimated at $23 million.

- In the ship industry: maintenance cost (hull cleaning and painting) is the main cost in the nautical sector, worldwide, followed by the increase in fuel consumption.

- Several recent studies estimate that the increase in fuel consumption due to biofouling on commercial vessels amounts to an additional 120 million tons per year.

- The total cost associated with fouling on ship hulls for the U.S. Navy in terms of coatings and cleaning is estimated to be in the region of $56 million per year for the DDG-51 class, reaching $1 billion over 15 years.

- In the aquaculture industry: biofouling and its impact on its equipment cause losses to the European industry of between 5 and 10% of the total value of the industry: up to €260 million per year. The cost derived from the need to renew nets in salmon farms is close to €60,000 per year, and in some sectors can represent up to 20% of operational costs.

- The zebra mussel infestation cost Endesa around two million euros in damages. By 2025, it is estimated that this species will have generated losses of up to 40 million euros in the Ebro basin. In the last 10 years, it is estimated to have caused around €1.6 billion in damages throughout Spain. In addition, it is estimated that maintenance pipes clogged with this species cost the energy industry around $60 million per year, and temporary stoppages caused by a reduction in water flow can cost up to $5,000 per hour.

- The costs of removing and controlling a species that has already colonized a structure are also very high. For example, removing the black striped mussel from Darwin Harbour cost around A$2 million, while the annual costs of controlling the proliferation of zebra mussels and quagga mussels in the North American Great Lakes is estimated to be between $100 million and $400 million.

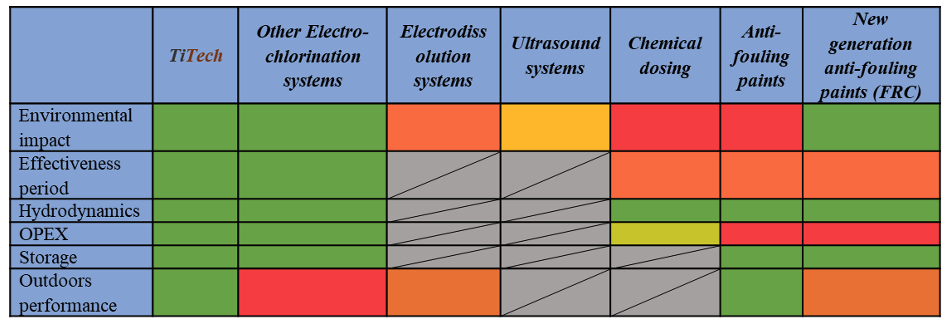

The following table shows a comparison of the different solutions existed in the market used to prevent biofouling based on their environmental impact and their maintenance necessities. The solutions that currently exist, however, are not sufficient to avoid it completely and/or create significant damage to the environment, therefore, this scenario reflects an unresolved problem in the fight against unwanted biofouling.

Green: good performance. Orange: regular performance. Red: Poor performance. Grey: not applicable.